Space exploration has always pushed the boundaries of technology and human ingenuity. One of the most promising advancements in recent years is the integration of 3D printing, or additive manufacturing, into space missions. This technology is revolutionizing how space agencies like NASA and private companies such as SpaceX approach the challenges of space travel and habitation. By enabling the on-demand production of tools, components, and even habitats, 3D printing is set to play a crucial role in the future of space exploration.

One of the primary benefits of 3D printing in space is its ability to reduce the dependency on Earth-based supply chains. Traditional space missions require all necessary equipment and spare parts to be pre-manufactured and transported from Earth, which is both costly and logistically complex. With 3D printing, astronauts can produce parts and tools on-site, as needed. This capability is especially critical for long-duration missions, such as those to Mars or the Moon, where resupply missions are impractical.

The International Space Station (ISS) has already demonstrated the practical applications of 3D printing in space. Since 2014, astronauts on the ISS have used a 3D printer to manufacture tools and spare parts. This technology has allowed them to address unexpected repairs and adapt to mission needs in real-time. For example, when a wrench was needed on the ISS, a digital design was sent from Earth, and the tool was printed on the station within hours. This on-demand manufacturing capability not only saves time but also reduces the weight and volume of cargo that must be launched into space.

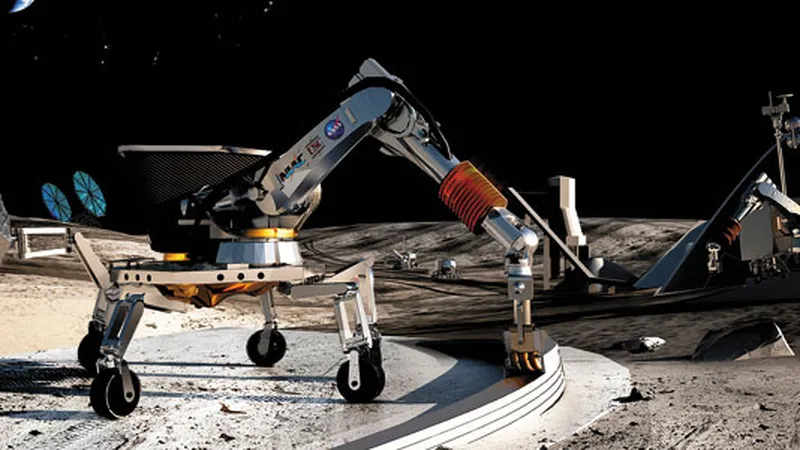

Beyond tools and spare parts, 3D printing holds the potential to revolutionize the construction of habitats and infrastructure on other planets. Building structures on the Moon or Mars using traditional construction methods would be extremely challenging and resource-intensive. However, 3D printing can utilize local materials, such as lunar regolith or Martian soil, to construct habitats and other essential structures. This process, known as in-situ resource utilization (ISRU), significantly reduces the need to transport construction materials from Earth, making extraterrestrial habitation more feasible.

In 2019, NASA conducted the “3D-Printed Habitat Challenge,” which invited teams to design and build habitat prototypes using 3D printing and local materials. The winning designs demonstrated the potential for constructing durable and sustainable habitats on Mars. Such advancements pave the way for future missions where astronauts could live and work in 3D-printed structures, enhancing their safety and comfort while reducing mission costs.

Another exciting application of 3D printing in space exploration is the creation of specialized scientific instruments and equipment. Researchers can design and print customized components tailored to specific experiments, enabling more versatile and adaptable research capabilities. This flexibility is particularly valuable in the dynamic and unpredictable environment of space, where mission requirements can change rapidly.

Moreover, 3D printing technology is evolving to include bioprinting, which involves printing biological materials. In the context of space exploration, bioprinting could be used to produce tissues and organs for medical purposes, addressing health challenges that may arise during long-term space missions. This capability would be a significant advancement in ensuring the well-being of astronauts on missions far from Earth, where medical assistance is limited.

3D printing also supports the development of more efficient propulsion systems. Rocket engines and other propulsion components can be manufactured using additive manufacturing techniques, allowing for intricate designs that improve performance and reduce weight. For instance, SpaceX has utilized 3D printing to produce parts for its SuperDraco engines, which are used in the Dragon spacecraft. These advancements contribute to more reliable and cost-effective space travel.

Despite the numerous advantages, the implementation of 3D printing in space exploration does face challenges. The space environment, with its microgravity and vacuum conditions, poses unique technical difficulties for additive manufacturing processes. Researchers and engineers are continually working to refine 3D printing technologies to ensure they function reliably in space. Additionally, the certification and standardization of 3D-printed components for use in critical mission applications remain crucial to ensure safety and reliability.

Looking to the future, the role of 3D printing in space exploration will only continue to expand. As technology advances, we can expect more sophisticated and versatile 3D printers capable of producing a wider range of materials and complex structures. The integration of AI and machine learning with 3D printing will further enhance the precision and efficiency of the manufacturing process.

By Our Media Team

Our Editorial team comprises of over 15 highly motivated bunch of individuals, who work tirelessly to get the most sought after curated content for our subscribers.